New EU rules for End-of-Life Vehicles

Published January 2026 © DATA4CIRC

Welcome to our first blog post of 2026!

You might have missed it over the holidays, but a new set of rules has been agreed which will cover circularity in the design, assembly, and end-of-life processing of vehicles and vehicle parts in the European Union. Read on to find out all you need to know!

What is the background to these new rules?

The automotive manufacturing industry ranks among the most resource-intensive sectors in the EU and is one of the largest users of primary raw materials. Each year, approximately 15 million vehicles are manufactured in the EU and around 6.5 million reach the end of their lives.

Currently, very little material from End-of-Life Vehicles (ELVs) is recovered or reused.

End-of-Life Vehicles in a scrap yard

What is the new agreement about?

The draft agreement between the European Parliament and European Council requires all new vehicles in the EU to facilitate the easy removal of parts and components for recycling etc. (see our blog on ‘R-strategies’) when the vehicle reaches the end of its lifespan. The agreement strengthens extended producer responsibility (EPR) by holding producers accountable for the full lifecycle of their vehicles.

Additionally, figures are set for the content of recycled materials to be used. For example, any plastic used in the new vehicles ought to contain at least 15% recycled materials (rising to 25% within ten years). Similar targets for metals such as steel and copper are under study according to the EU’s Press Release. Before the newly agreed rules come into force, they must be formally approved by both the Parliament and Council.

How will this affect DATA4CIRC?

Whilst this does not affect the DATA4CIRC project at the current time because our Use Case #1 deals with agricultural plastics (i.e. Low-Density Polyethylene) rather than Polypropylene and polyurethane most commonly used in cars and our Use Case #3 deals with the metals recoverable from automotive catalytic converters only, the new rule is exciting for a number of reasons.

So why are we talking about it?

Any legislation requiring increased use of recycled material will necessarily drive demand for reliable and efficient ways of ensuring that material purported to be recycled is, in fact, recycled. To avoid fraud and public mistrust when it comes to recycled materials, various solutions have been proposed. The DATA4CIRC platform will, through the use of Digital Product Passports, offer a way of ensuring material is traceable throughout its lifecycle.

Digital Product Passports could also contribute to resolving the problem of so-called ‘missing vehicles’ (around 3.5 million vehicles ‘disappear’ from official records each year without being properly reported to authorities as having reached their end-of-life. This lack of traceability undermines recycling rates and leads to illegal dismantling, improper disposal, or non-roadworthy exports).

The new rules, when the enter force, will reshape investment and supply chains. This is likely to result in a cascade of increasing use of recycled materials in other automotive components. It represents a great opportunity for DATA4CIRC’s platform

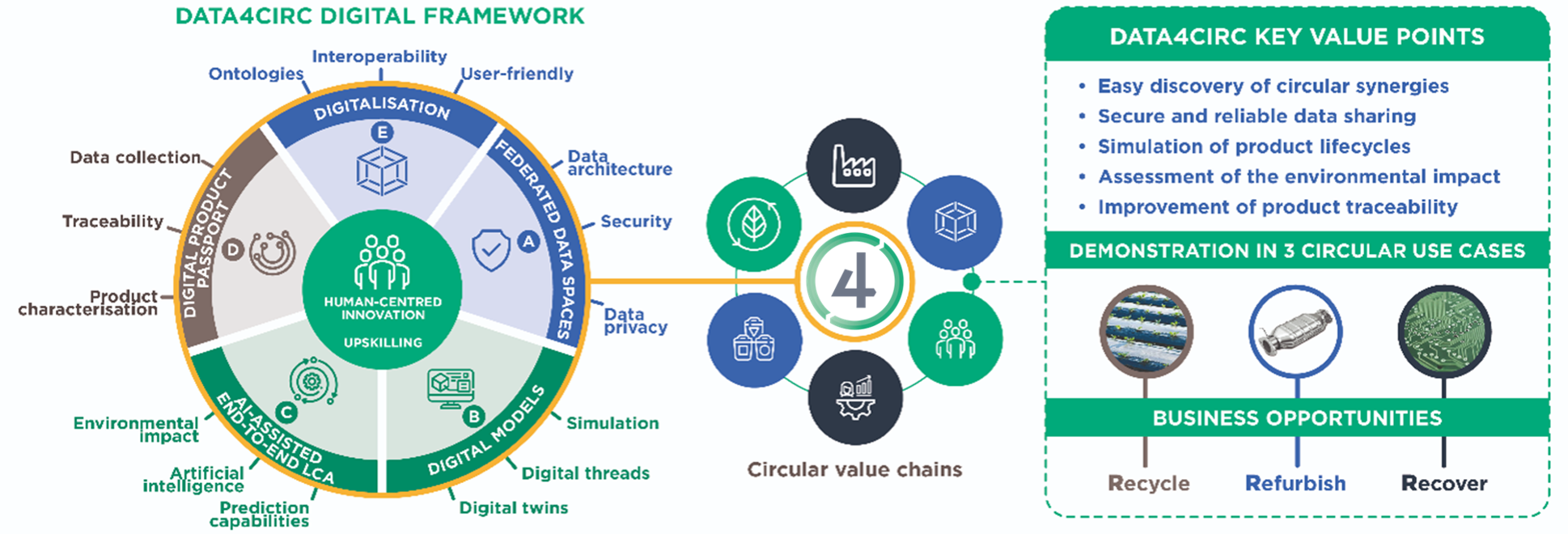

The DATA4CIRC concept © DATA4CIRC 2026

We hope you are as excited as we are to follow the DATA4CIRC journey! You can keep up to date on the latest developments from our project by following us on the DATA4CIRC social media channels: