Plastic: Fantatsic? Part 2 - different types

Published August 2025 © DATA4CIRC

In DATA4CIRC’s last blog we looked at what plastics are and learned about the history of their invention and began considering some of the problems their widespread adoption has caused. Now it’s time to take a closer look at the different key types of plastic (from a recycling perspective).

Recycling – the different types of plastic

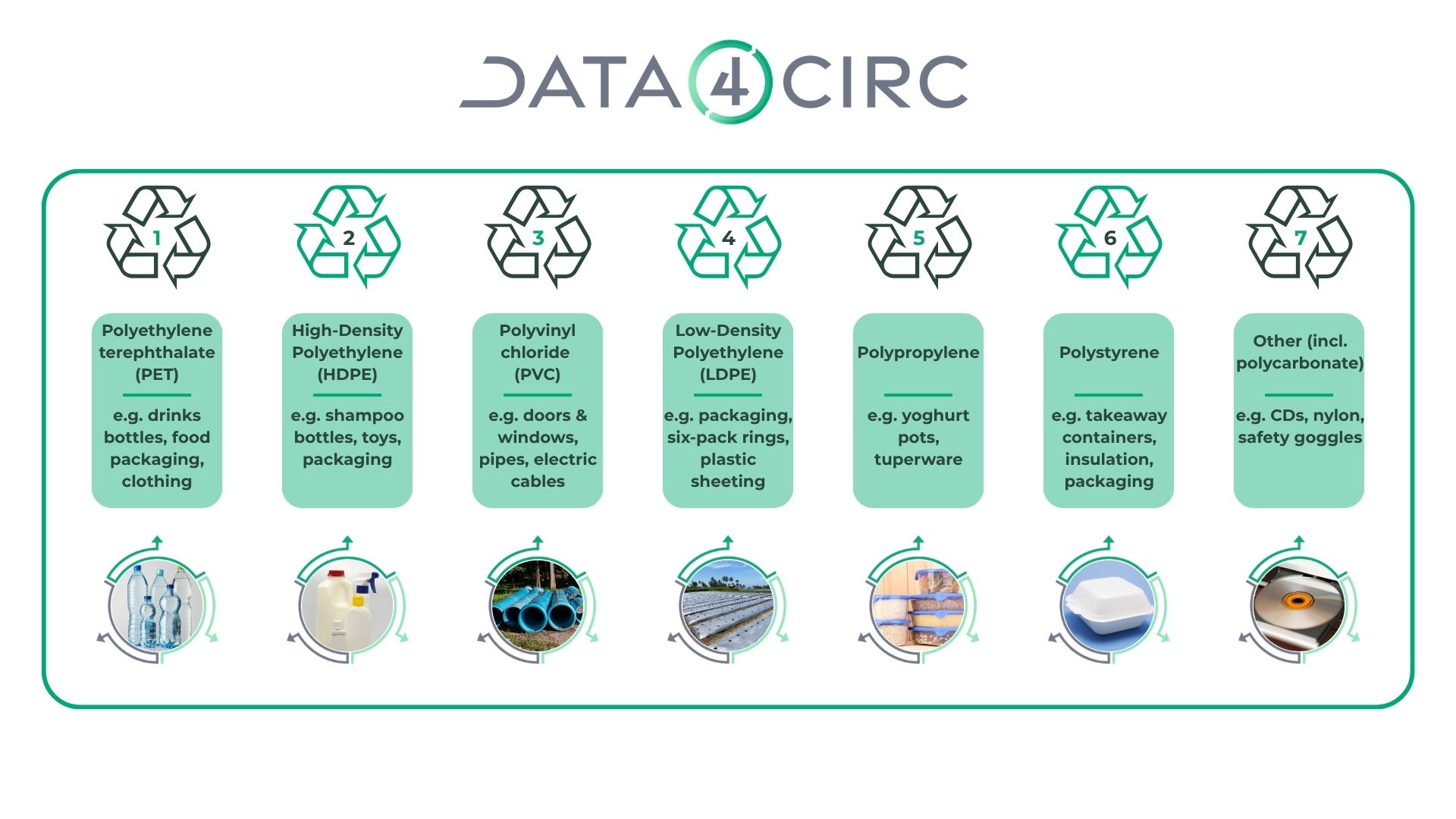

Each type of plastic is different – it has different uses, different properties, and different requirements when it comes to recycling. In 1988, the Society of the Plastics Industry introduced the Resin Identification Code (RIC) system which divided plastic resins into 7 different categories.

The seven categories of plastic are as follows:

1. PET (Polyethylene teraphthalate)

Polyethylene teraphthalate is a strong and highly versatile plastic with many uses. It is a thermoplastic, which means it can be repeatedly melted and reshaped. One of the most common uses for it is plastic drinks bottles: approximately 500 billion PET bottles are sold globally every year. The good news is, these can be relatively easily recycled into new bottles or into products such as clothing (Polyethylene terephthalate is known as PET when used in bottles, but when used as a fibre, it is known as Polyester), construction materials, or home goods. PET recycling can save 83% of the energy and 70% of the CO2 emissions necessary for PET produced from virgin material. The bad news is that despite PET being the most widely recycled plastic in the world, most of it still is not recycled as proper collection/sorting is vital to avoid contamination. You can find out more about the current status of Polyethylene terephthalate recycling here.

PET bottles – you’ve probably used one in the last 24 hours.

2. HDPE (High-Density Polyethylene)

High-Density Polyethylene, also a thermoplastic, is known for its high strength-to-density ratio and relative rigidity, which make it well-suited for moulding. HDPE is therefore most commonly used in rigid packaging such as bottles for milk and household chemicals, as well as heavy duty items such as pallets, drums, and other containers. It can also be used for heavy duty packaging and screw caps though, due to HDPE’s susceptibility to stress-cracking, Polypropylene may be used where caps are required for long-term usage. HDPE is also easy to recycle, though a barrier to this may be a lack of infrastructure in many locations. In Europe only about 10-15% of all HDPE is recycled after use.

3. PVC (Polyvinyl Chloride)

Polyvinyl Chloride, like PET and HDPE, a thermoplastic, is lightweight and strong. It can be rigid or flexible, depending on which additives are included in the production process. Its fire-resistance and resistance to weathering, abrasion, and corrosion make it ideal for use in construction (for example, window frames, flooring, and pipes). It is also frequently used in consumer goods such a water-proof coats and shower curtains, and in the automotive sector. Despite concerns over its environmental impact, the PVC industry is expected to be worth almost 87€ billion by 2031. PVC is harder to recycle than PET or HDPE due to its chlorine content and as it frequently contains additives. However, for each tonne of PVC recycled, two tonnes of CO2 are saved.

PVC window frames – you’ve probably got some in your home.

4. LDPE (Low-Density Polyethylene)

Due to its flexibility, resistance to degradation by chemical and/or environmental factors, which helps provide a long service life, its low cost compared to other plastics, and ease of processing, LDPE has many uses, including plastic shopping bags, food packaging, and agricultural films like greenhouse covers and mulch film. LDPE is also a thermoplastic.

Proper sorting and treatment are key to successful recycling of LDPE. It is LDPE that is the focus of DATA4CIRC’s Use Case #1, which aims to turn used agricultural plastics (specifically, mulch film and greenhouse covers) into high-quality recycled products, promoting sustainability in the agricultural sector. The recycling of plastics from agriculture in Europe is very limited due to high contamination with soil and organic matter: in 2021, only 24% of non-packaging agricultural plastic waste was recycled. DATA4CIRC’s partners Green World Compounding (GWC) and Centro Tecnológico del Calzado y del Plástico de la Región de Murcia (CETEC), both based in Murcia, Spain, are working on innovative ways to make the cleaning of the contaminated waste more efficient and ensure the minimisation of fumes during recycling. During the washing process, organic residues, pesticides, and soil are removed, and the resulting water is treated in an internal treatment plant at GWC. In addition, the subsequent extrusion process is equipped with gas extraction chambers that operate under vacuum, allowing the gases generated by the heating of the plastic to be extracted, while also preventing them from reacting within the vacuum atmosphere of the chamber, thus avoiding the production of contaminants and ensuring the resulting material is safe.

The DATA4CIRC platform will help GWC further refine their processes by allowing them to better trace the origin of the materials they are recycling and, above all, control process efficiency according to the contamination present in the waste, helping to adjust parameters and predict, in a bespoke way, the amount of stabilising additive each batch requires, thus adapting to the demand for waste present in the market. In turn, the processor (CETEC) will obtain higher-quality materials, allowing them to preserve some of the properties that would otherwise have been lost during the lifetime of the original plastic.

LDPE sheeting on a farm: plastic mulch in walk-in greenhouse polyethylene tunnels. LDPE from agriculture will be the focus of DATA4CIRC’s Use Case #1

5. Polypropylene

Polypropylene, another thermoplastic, is, lightweight and resists fatigue, making it well-suited for applications in which it must withstand bending and twisting, such as plastic hinges. It makes up approximately one sixth of the plastic used globally. It can be recycled though, due to it often being blended with either natural or artificial fibres or with various biodegradable polymers, proper separation can prove challenging.

6. Polystyrene

Polystyrene can come in solid or foam (often known by its commercial name ‘Styrofoam’) form. Most people are familiar with the latter form. Its light weight, relative rigidity, and excellent insulation properties mean polystyrene foam is used for products such as single-use coffee cups and product packaging as well as in the construction industry. Whilst it is possible to recycle polystyrene, the recycling process is relatively complex and the infrastructure for doing so is, in many locations, simply not available. This limits the potential for polystyrene to be recycled. As it does not biodegrade, polystyrene can persist in the environment for a long time, which can make it highly problematic for wildlife, which may mistake it for food and ingest it.

Styrofoam showing the recycling symbol

7. Others

This is, as it sounds, a catch-all group for plastics which do not fall into categories 1-6. There are many other kinds of plastic (such as Polycarbonate, Polyurethane, Nylon, and Acyrlic, as well as bioplastics like Polylactic Acid) and, whilst some of them can be recycled, the reality is that the frequently end up in landfill, where even supposedly ‘biodegradable’ plastics may not, in fact, have the right conditions to fully breakdown.

A summary of the different types of plastic for the purpose of recycling

Final thoughts

In tracing the fascinating journey of synthetic plastics – from their revolutionary beginnings to the complex recycling codes the exist today – we see both the potential and the challenges of this versatile material. Understanding the seven types of plastic and how they are recycled is crucial not only for informed consumer choices but also for shaping a more sustainable future. At DATA4CIRC, we’re taking this knowledge further by applying data-driven approaches to real-world challenges, including boosting the recycling of agricultural plastics through enhanced traceability and lifecycle analyses.

If you’re interested in how digital innovation can support circular economy solutions, we invite you to follow our progress and stay connected as we turn insights into action.

You can keep up to date on the latest developments from our project by following us on the DATA4CIRC social media channels: