Use Case #2: Reimagining E-Waste Management – The Circular Value Chain for Waste from Electrical and Electronic Equipment (WEEE)

The Circular Value Chain for Waste from Electrical and Electronic Equipment (WEEE) is transforming how we manage electronic waste, extending the life cycle of electronic products while minimising e-waste. This innovative approach is led by two key partners working together to tackle waste generation and recovery in the WEEE sector, Gruppo FOS, and Eco Recycling.

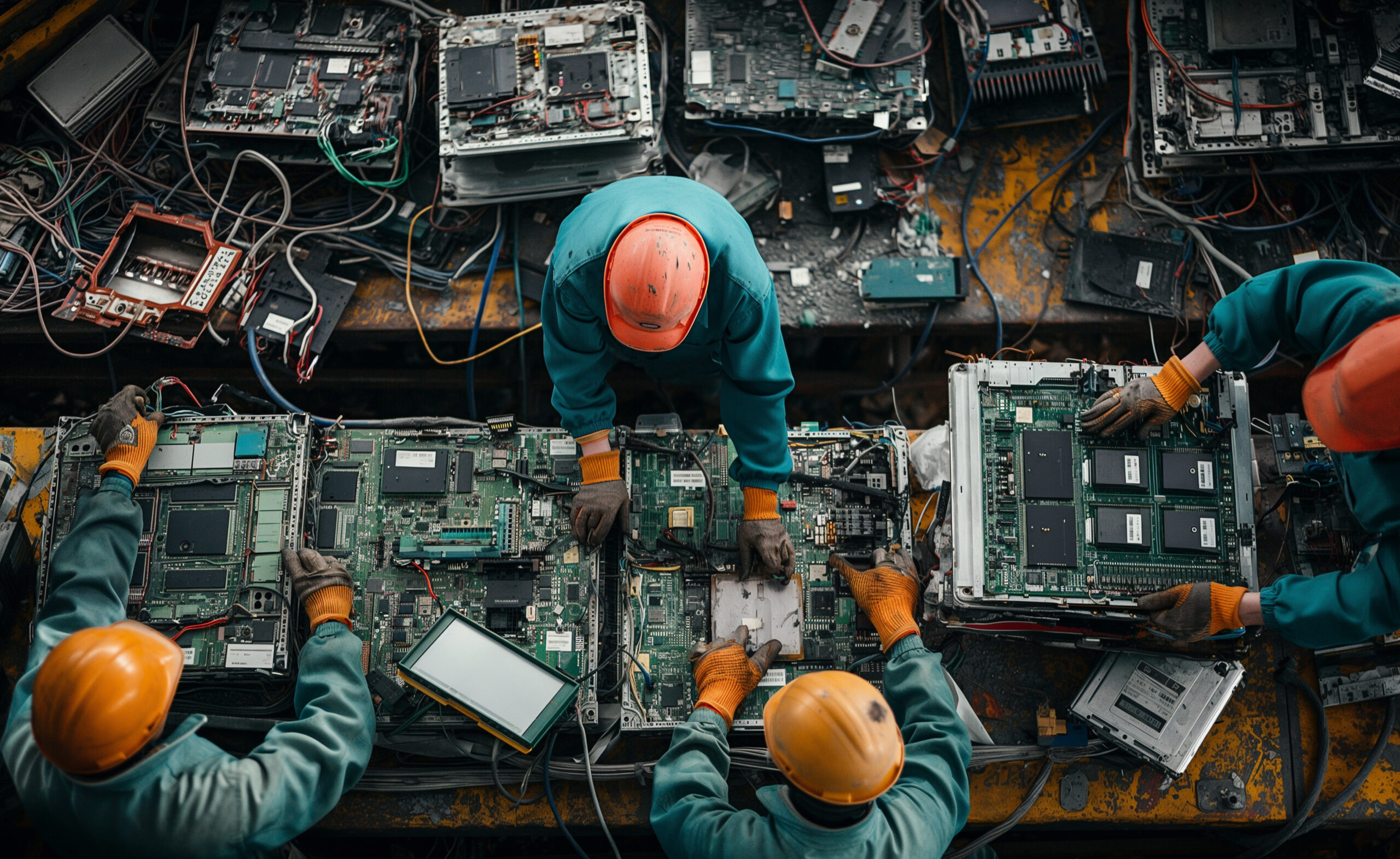

FOS T&G repair & re-manufacturing centre leads the charge by repairing electronic boards, a process that generates waste, including faulty components and materials. Instead of discarding this waste, Eco Recycling processes it to extract valuable secondary raw materials. These materials are then reused to produce new electronic components, creating a closed-loop system.

By integrating these processes, we regenerate valuable materials, reduce the environmental impact of e-waste, and conserve resources in manufacturing new electronics. This collaboration aligns with circular economy principles, promoting the reuse, re-manufacture, and recycling of electronic components.

This initiative not only fosters sustainability but also enhances efficiency in the WEEE sector.